Chemical Recycling

our approach aimed at maximizing productivity & efficiency.

CEO, NUGA RECYTECH d.o.o.

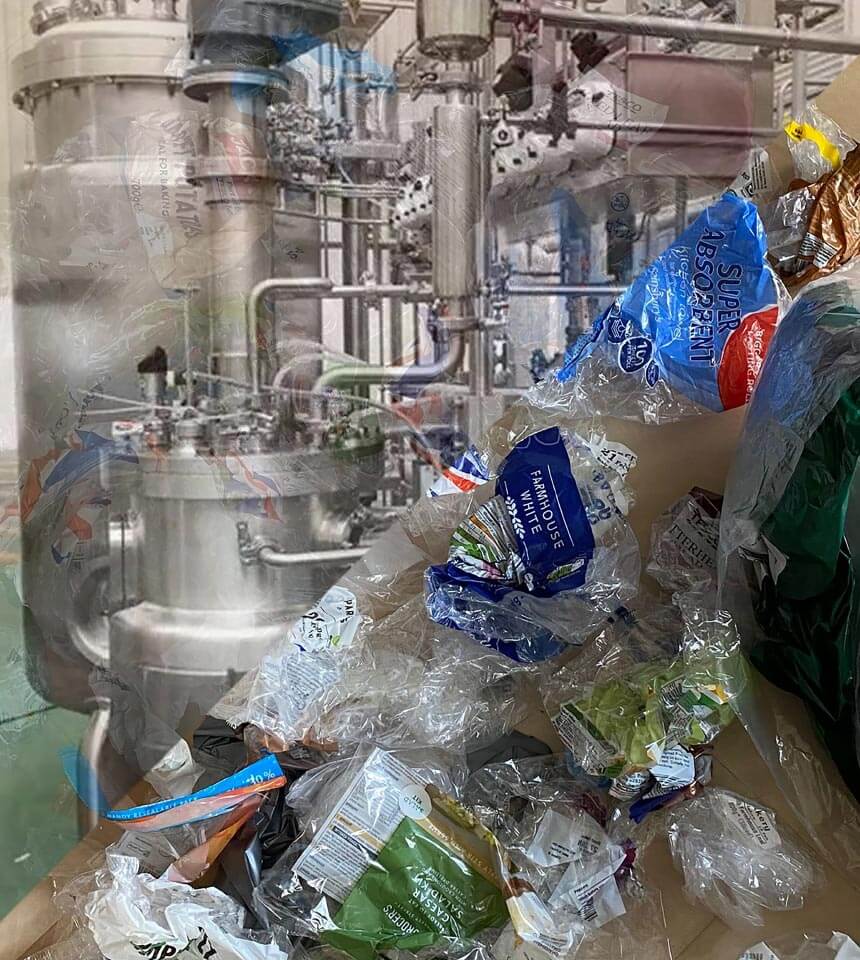

Compact Pre-Treatment Plants for Chemical Recycling

NUGA RECYTECH provides state-of-the-art compact pre-treatment plants designed to transform mixed or highly contaminated plastic waste into high-quality feedstock for chemical recycling processes. Our advanced systems efficiently remove impurities and prepare materials, ensuring optimal processability for downstream technologies such as pyrolysis or depolymerization.

Purpose of Pre-Treatment in Chemical Recycling

Contaminant Removal

Effectively separates unwanted materials—including paper, wood, metals, and incompatible plastics—ensuring only suitable plastics advance to chemical recycling.

Plastic Sorting by Composition

Utilizes cutting-edge technologies (NIR sorting, density separation, etc.) to sort plastics by chemical type, which is critical for achieving consistent and efficient recycling results.

Material Preparation for Processing

Prepares plastics into the ideal form—cleaned, shredded, and dried—for seamless integration into chemical recycling systems.

Why Pre-Treatment is Critical?

Enhanced Efficiency

By removing contaminants and sorting materials, our pre-treatment systems maximize the throughput and operational efficiency of chemical recycling plants.

Superior Product Quality

Clean, well-sorted feedstock improves the purity and quality of recycled outputs, supporting production of high-grade polymers and fuels.

Economic Sustainability

Reduces the need for costly purification at later stages, making chemical recycling more economically viable.

Key Pre-Treatment Processes

Physical Methods:

• Shredding and crushing for size reduction

• Sorting via advanced optical (NIR) and density separation technologies

• Intensive washing and drying for contaminant removal

Modular Design:

• Compact and space-efficient

• Low energy consumption and minimal maintenance requirements

• Scalable to fit various plant capacities

Benefits of NUGA RECYTECH Pre-Treatment Plants

Compact & Modular Configuration

Easily integrated into existing chemical recycling plants or deployed as stand-alone units.

Cost-Effective Operations

Designed to balance investment and operational efficiency for long-term economic returns.

User-Friendly Systems

Simplified handling with low space, energy, and maintenance requirements.

A Vital Link in the Chemical Recycling Value Chain

Pre-treatment plants are a key enabler for the circular economy, ensuring plastic waste is efficiently converted into high-value raw materials for sustainable production.

Why Choose NUGA RECYTECH?

Wide Application Range

Solutions designed for multiple industries and waste streams.

Scalable Systems

From stand-alone machines to complete turnkey plants.

Tailor-Made Recycling Solutions for Diverse Industries

Headquarter

Bozidara Adzije 19

44000 Sisak

Croatia

Production

Mala Svarca 155

47000 Karlovac

Croatia

Contact Us

+385 91 3636398

nuga@nuga-recytech.com

© 2012 - 2025 NUGA RECYTECH d.o.o. • All Rights Reserved • Developed by DobarPotez