Recycling Solutions

our approach aimed at maximizing productivity & efficiency.

CEO, NUGA RECYTECH d.o.o.

Complete Recycling Solutions for Plastic Waste

At NUGA RECYTECH, we offer comprehensive, tailor-made solutions for plastic waste recycling—designed to meet your specific material type, capacity requirements, and quality expectations. Our advanced system concepts and high-performance machinery consistently deliver recycled materials with properties comparable to virgin polymers.

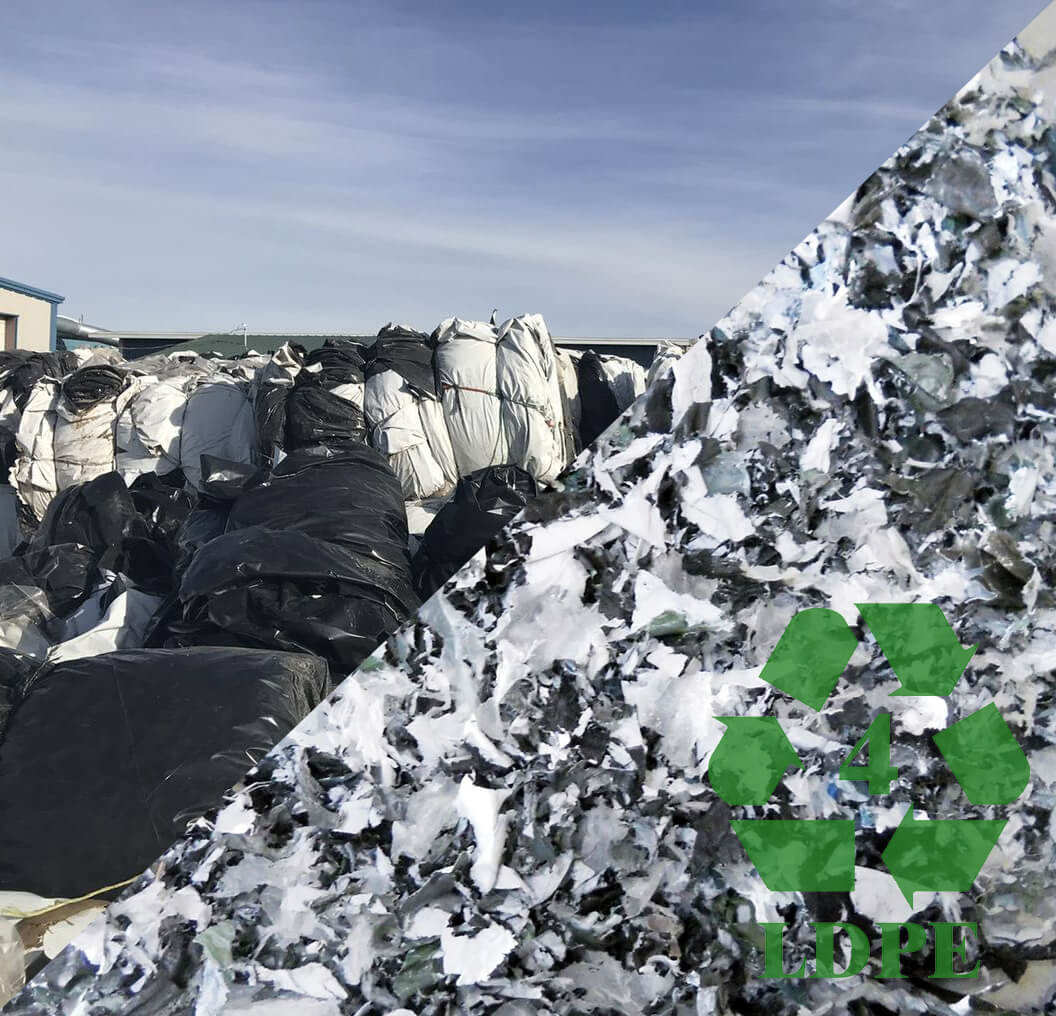

PE – Polyethylene Recycling

Post-Consumer Film (LDPE / HDPE)

Post-consumer polyethylene films, primarily sourced from household and municipal waste, are often heavily contaminated with organic residues, dirt, and other impurities. These materials require thorough sorting followed by shredding, multi-stage washing, and granulation. The complexity of this process demands robust, high-quality machinery and a proven recycling concept—both of which NUGA RECYTECH delivers.

Post-Commercial Film (LDPE / HDPE)

Commercial films, including stretch film from logistics and retail sectors, are extremely thin and highly elastic. They often carry contamination from labels, adhesives, organic residues, and sometimes soil or glass. Our systems are engineered to manage these challenges efficiently, ensuring clean, high-quality regranulates.

Agricultural Films (LDPE / LLDPE)

Agricultural waste films such as bale wrap, silage sheets, mulch films, and greenhouse covers are typically exposed to heavy contamination. Our solutions incorporate shredding, pre-washing, intensive washing, and drying stages to deliver exceptionally clean, transparent recyclates.

HDPE Rigid Waste (Bottles & Canisters)

• HDPE Bottles: Often baled and pre-sorted, their quality varies by region and waste management practices. NUGA RECYTECH CompactTech systems consistently achieve high-quality output and ensure the profitability of recycling operations.

• HDPE Canisters: As bulky monofractions, they require careful shredding and washing. Contaminants like oils and chemicals are effectively removed using our integrated washing lines and advanced water treatment systems.

PP – Polypropylene Recycling

PP Woven Bags

Recycling PP woven bags is highly challenging due to abrasive residues such as sand, cement, and glass. Our systems are equipped with wear-resistant components and include additional spare parts packages to ensure minimal downtime and reliable operation even under extreme conditions.

PP Boxes, Plates, Profiles & Solid Waste

This category includes bulky packaging waste sourced from retail or industrial sites. The process of grinding and washing is less demanding compared to woven bags. Our friction washers deliver outstanding cleaning performance without degrading material properties.

Key Technology:

• NST Flotation Tanks: Efficiently separate polyolefins (PO) from heavier fractions (>1 g/cm³) based on specific density.

PET – Polyethylene Terephthalate Recycling

PET Bottles

NUGA RECYTECH provides specialized recycling concepts for PET bottles, tailored to contamination levels and end-use requirements (e.g., food-grade packaging or textile fibers).

• Debaler Openers: Heavy-duty machines with capacities up to 6 t/h.

• Granulators with Force Feeding: Ensures high throughput and consistent flake quality, with rotor designs that minimize fines formation.

PVC – Polyvinyl Chloride Recycling

PVC Pipes & Profiles

Our PVC recovery systems handle both post-industrial and post-consumer waste. The process includes:

• Primary cutting with granulators

• Pulverizing to fine powders (500–700 microns)

• Vibrating sieves for precision screening

• Filtration and pneumatic conveying systems

Where necessary, additional washing modules are available.

Key Technology:

• NPZ Fine Mills: High-quality pulverizers available in multiple sizes with capacities up to 1 t/h.

Other Thermoplastic Waste

NUGA RECYTECH also provides customized recycling solutions for a wide range of thermoplastics, including:

• Automotive Plastics: Bumpers, interior parts, tanks (PP, ABS, PS).

• Extrusion Lumps: Large chunks formed during production processes.

• Insulation Materials: Styrofoam and mineral wool, with specialized shredding and preparation systems.

• Car Battery Plastics: Turnkey recycling systems for automotive battery casings and components.

Why Choose NUGA RECYTECH?

Wide Application Range

Solutions designed for multiple industries and waste streams.

Scalable Systems

From stand-alone machines to complete turnkey plants.

Tailor-Made Recycling Solutions for Diverse Industries

Headquarter

Bozidara Adzije 19

44000 Sisak

Croatia

Production

Mala Svarca 155

47000 Karlovac

Croatia

Contact Us

+385 91 3636398

nuga@nuga-recytech.com

© 2012 - 2025 NUGA RECYTECH d.o.o. • All Rights Reserved • Developed by DobarPotez