Recycling Machines and Equipment

our approach aimed at maximizing productivity & efficiency.

CEO, NUGA RECYTECH d.o.o.

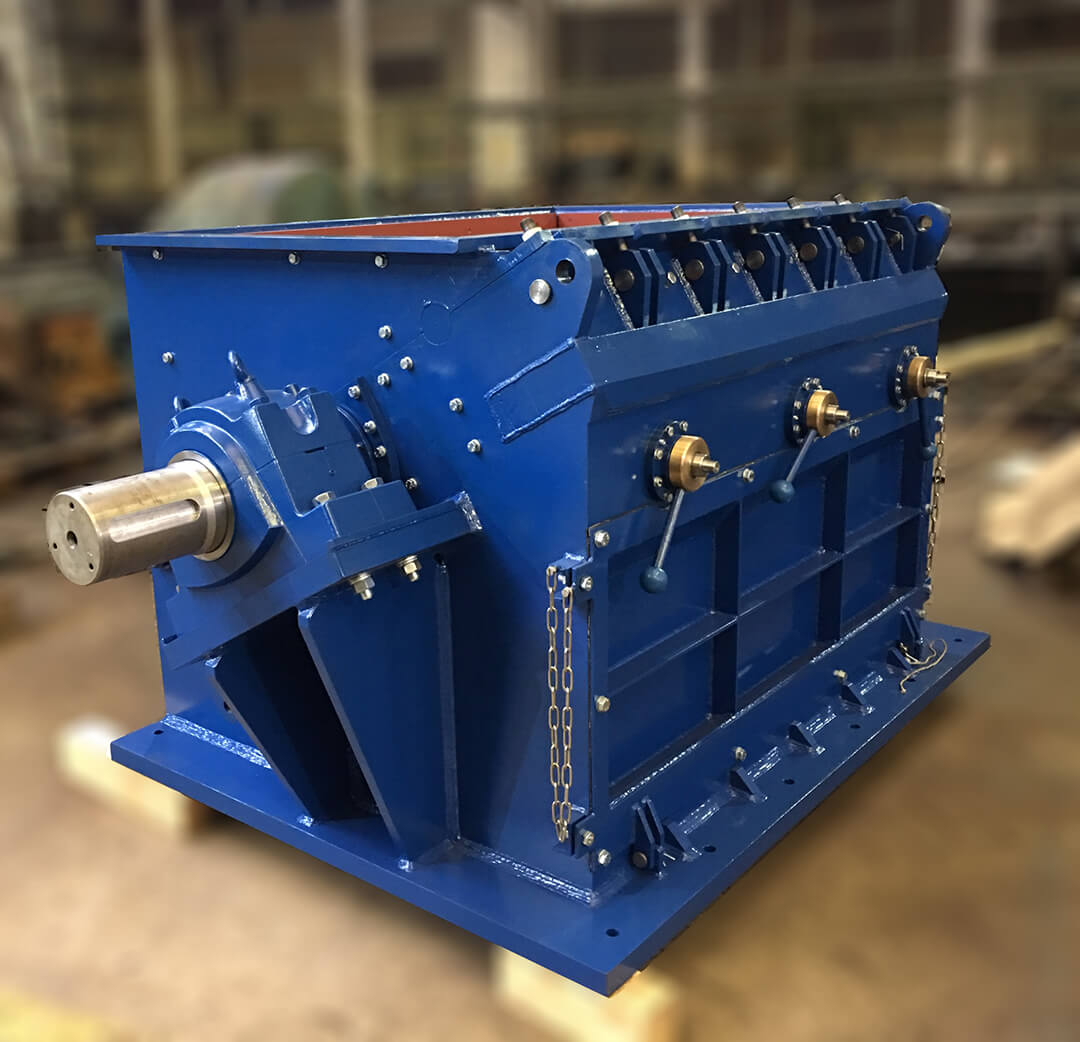

Pre-Size Reduction

Screw Crushers / Bale Breakers

The NUGA NSC/NBB series represents a new generation of slow-speed crushers equipped with 2, 4, 6, or 8 independently mounted screw shafts. Each screw operates separately within a robust chassis for optimal performance.

Engineered for the size reduction of brittle materials such as wood, porous blocks, insulation wool, and other bulky waste, these machines excel in handling contaminants like glass, metal, or stones without compromising efficiency.

The NUGA MBB models are particularly effective as bale breakers/openers for PET bottle bales, achieving processing rates of up to 6,000 kg/h depending on material bulk density.

Key Features:

• Heavy-duty construction for highly compacted bales

• Variable speed control for process flexibility

• Expanded metal enclosure for safe, visible operation

• High capacity design with configurable discharge options

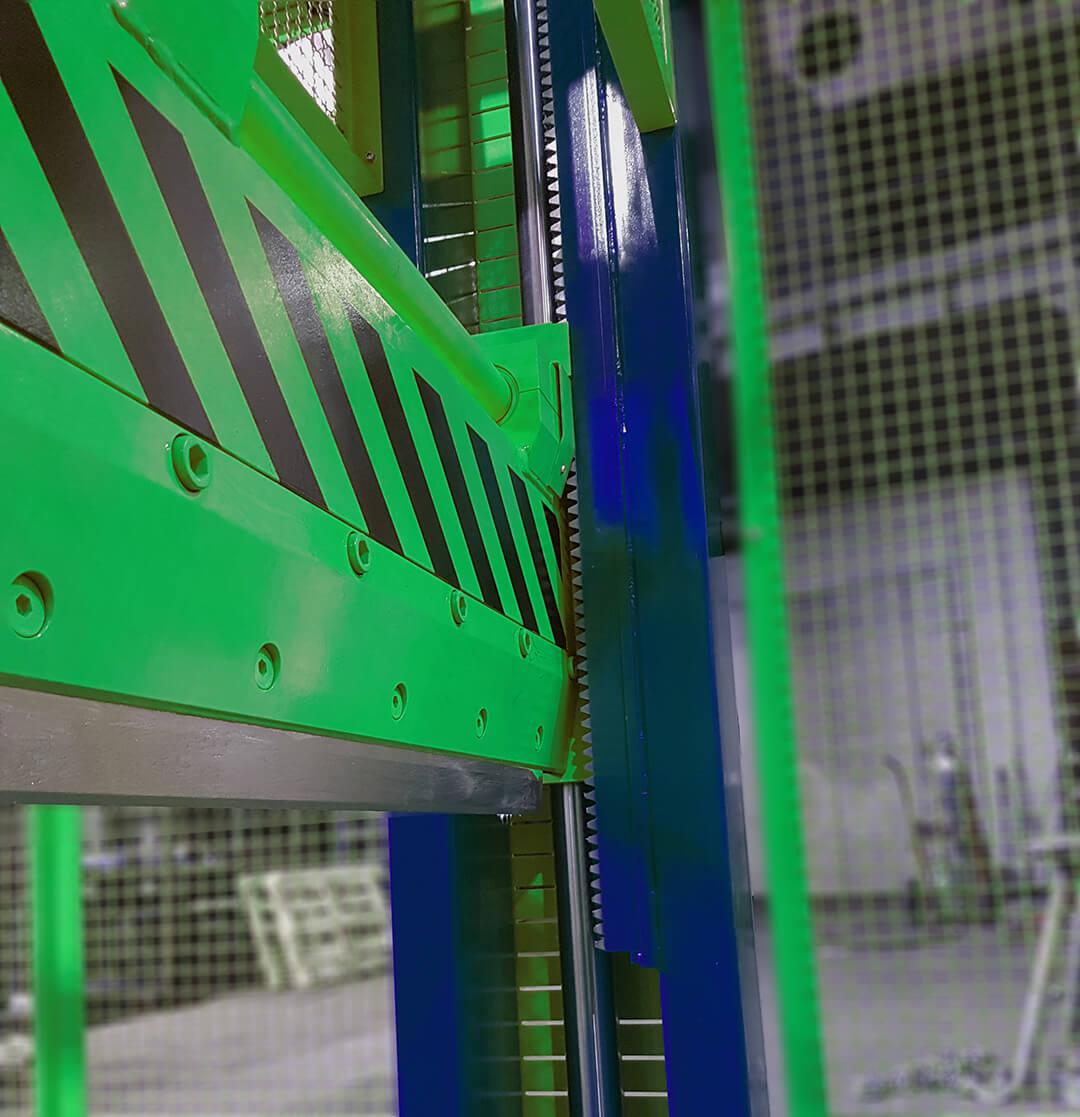

Guillotines

The NUGA NGC guillotine is purpose-built for the pre-size reduction of challenging materials such as plastic film bundles, multifilaments, carpets, fiber bales, fishing nets, and rubber bales. Each unit is tailored to accommodate the dimensions of specific rolls or bundles, with a range of feeding and discharge systems to suit customer needs.

Key Features:

• Exceptionally strong machine body for demanding applications

• Advanced pump control technology for reduced noise levels

• Vibration-dampening design for stable operation

• Fully adjustable strokes, speeds, and pressure settings

Shredders

The NUGA NSS single-shaft shredder series delivers powerful and efficient size reduction in a single step. Designed for bulky waste, including plastic film, woven bags, and both soft and rigid thermoplastics, these shredders offer unmatched versatility and process control.

Key Features:

• Low energy consumption with high throughput

• Wide range of sizes and configurations

• Intelligent monitoring and automated control systems

• Extensive knife options for tailored particle sizes

• Robust design for consistent performance in demanding applications

Primary Size Reduction

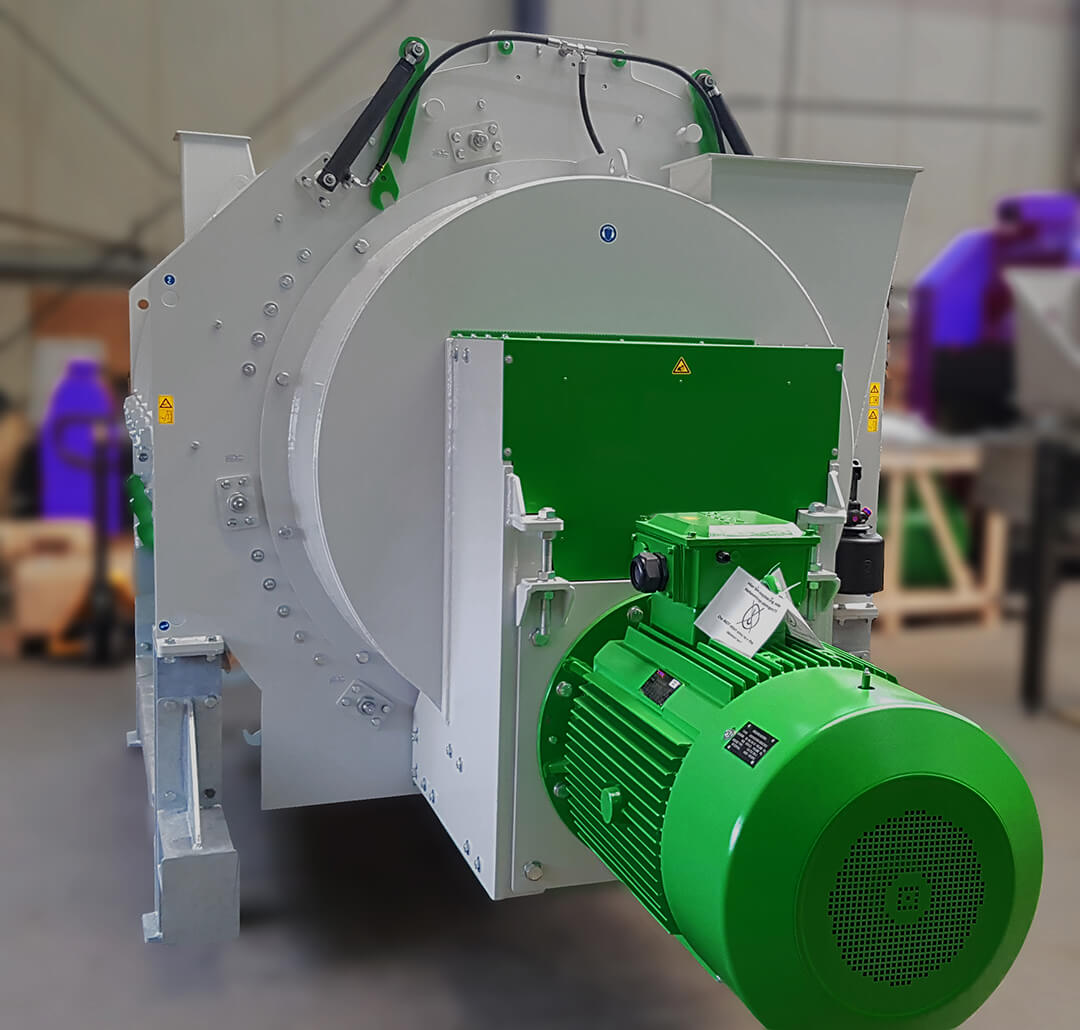

Granulators

The NUGA NG series granulators combine compact design with rugged construction to handle a wide range of plastics processing tasks. Available in both dry (NG) and wet (NWG) versions, as well as specialized models—NPG for profiles, NTG for pipes, NGRF with roller feeders, NGG with guillotine rotors, and NGX for extreme heavy-duty applications.

Key Features:

• Energy-efficient operation

• Universal applicability across diverse materials

• Easy maintenance with simplified access to cutting areas

• Oversized bearings isolated from the housing for longer life

• Broad selection of machine sizes and rotor designs

Fine Size Reduction

Pulverizers

The NUGA NPZ series is a high-speed, precision pulverizer ideal for processing semi-rigid, impact-resistant, and brittle plastics such as PVC, HDPE, and PP into fine powders for rotational molding and other high-demand applications.

Typical Applications:

• Rotational molding industry

• Masterbatch production

• Coating powder manufacturing

• Compounding and extrusion

Key Features:

• Minimal material residence time to reduce thermal degradation

• Simplified disc gap adjustment for optimal efficiency

• Uniform powder quality

• Cost-effective and high-performing design

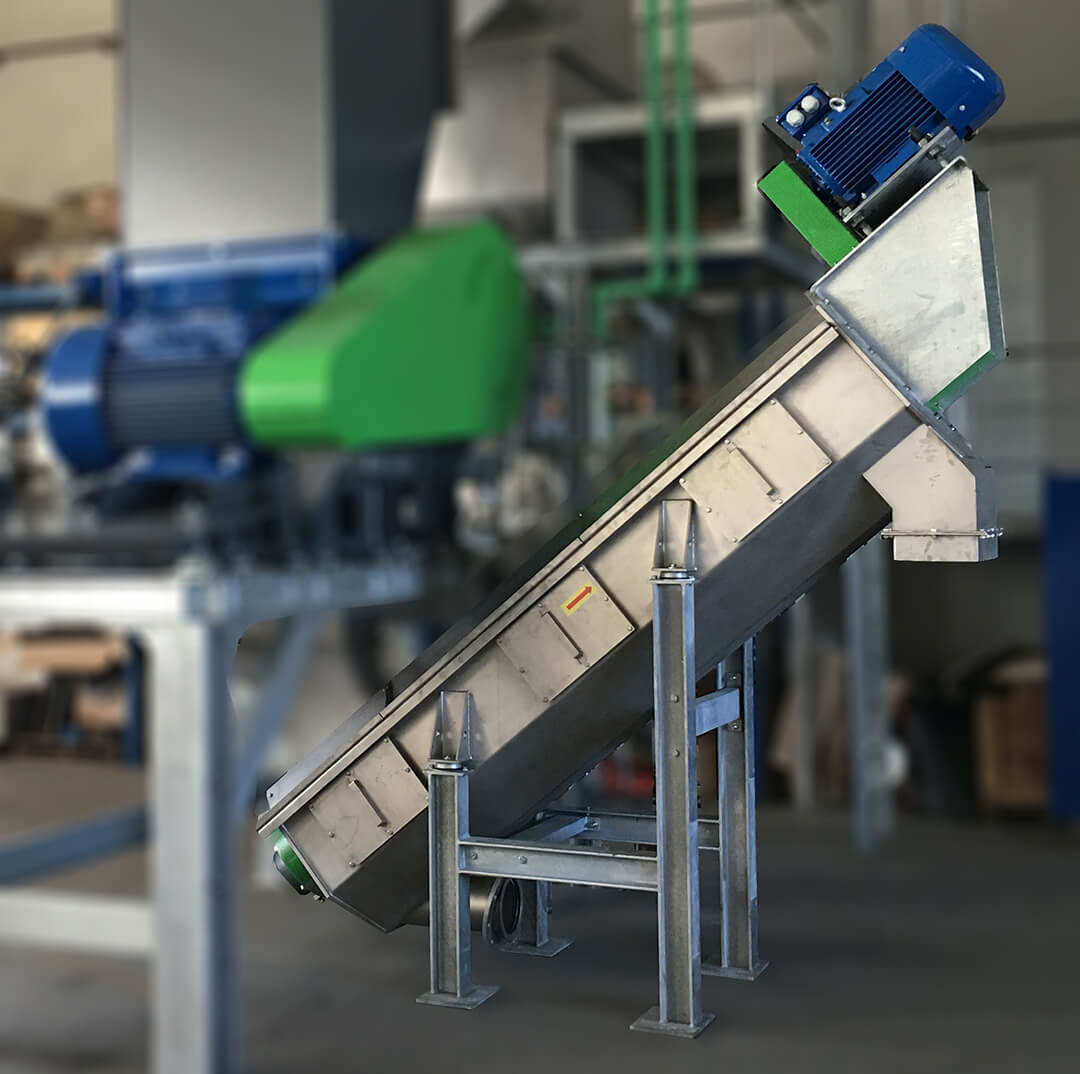

Pre-Wash Technology

Pre-Wash Tanks

The NUGA NPT pre-wash tanks efficiently separate heavy contaminants like stones, sand, and glass, safeguarding downstream equipment and optimizing the recycling process.

Key Features:

• Superior impurity separation

• Modular design for scalability

• Constructed entirely of stainless steel (1.4301)

• Flexible discharge options via chain conveyor, auger, or drain valves

Note: For specific requirements, NUGA also offers alternative pre-wash solutions such as augers and rotary separators for extremely contaminated materials like agricultural films.

Primary Intensive Washing

Friction Washers

The NUGA NFW series delivers intensive cleaning of highly contaminated plastics, including foils, PET, and rigid bottles. Designed for continuous material transport and water circulation, they ensure effective washing and pre-drying in a single process.

Key Features:

• Enhanced perforated surfaces for improved separation

• Replaceable rotor paddles and easy sieve access

• Stainless steel construction (1.4301) for durability

• Efficient removal of contaminants and moisture

Separation Technology

Separation Tanks

The NUGA NST series facilitates density-based separation of plastics (e.g., PE from PET), ensuring precise fractionation through optimized tank geometry and variable material flow.

Key Features:

• Automated water level control

• Variable motor speed for precise flow management

• Stainless steel tank construction with galvanized steel supports

Dry Separation (Air Sifters)

The NUGA NZZ zig-zag air sifters employ cross-flow sieving to separate light and heavy fractions. Ideal for improving final product quality or preparing materials for further processing.

Key Features:

• Modular system design

• Multiple discharge options (gravity, screw, or pneumatic)

• Clear process visibility and easy maintenance

Drying Technology

Mechanical Dryers

The NUGA NMD series uses centrifugal force to effectively remove moisture from both soft (PE films, PP bags) and hard (PET, HDPE bottles) materials.

Key Features:

• High drying efficiency with reinforced rotors

• Stainless steel sieves with segmental design for easy replacement

• Oversized external bearings for enhanced durability

• Compact, low-maintenance construction

Thermal Dryers

The NUGA NTD thermal dryers reduce extreme moisture levels (<5%) for pelletizing and further processing. Featuring a 30-meter drying path and integrated air handling systems, they deliver optimal drying results.

Key Features:

• Central air suction and heated airflow

• Mixing cyclone and rotary valve discharge

• Fully automated control systems

Storing Technology

Silos

The NUGA NBS silos are engineered for intermediate storage of materials with challenging flow characteristics. Horizontal design and integrated screw discharge systems ensure smooth operation.

Key Features:

• Large storage volumes with minimal energy use

• Optimized for low maintenance and reduced operating costs

• Optional single or double auger systems

Equipment

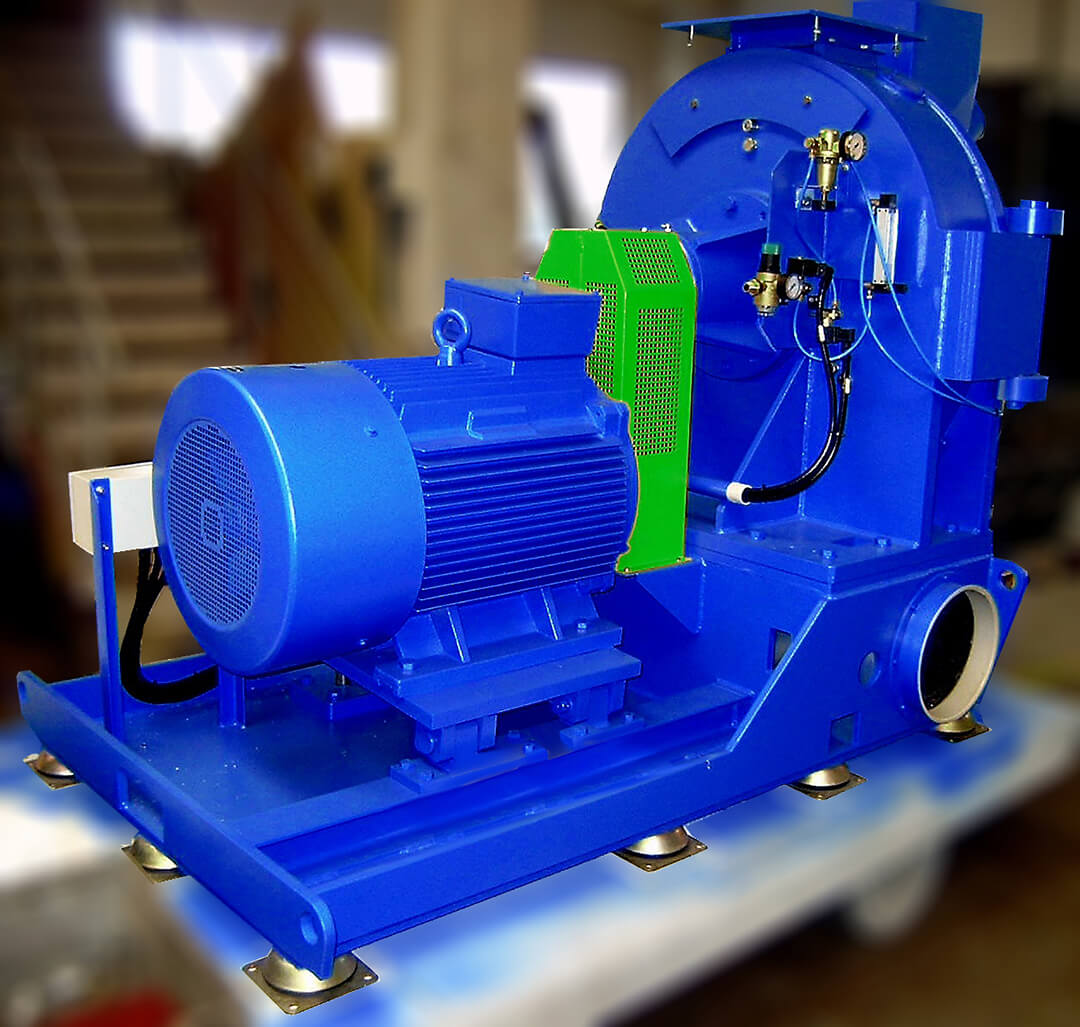

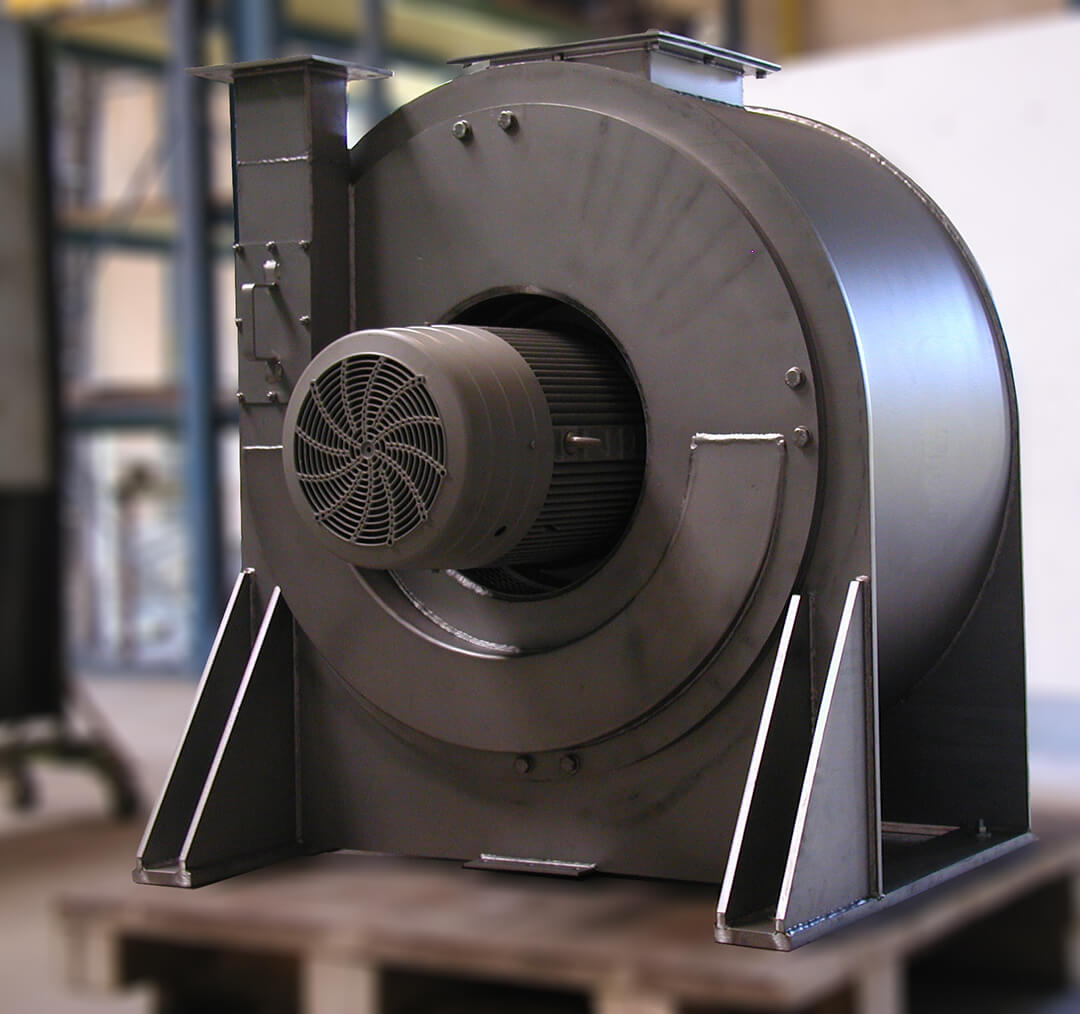

Blowers

The NUGA NTB series blowers, available in standard and stainless steel with optional protective coatings, provide reliable material transport for diverse recycling streams.

Cyclones

High-efficiency NUGA cyclones are built in two-part flange-connected designs for easy installation and orientation flexibility. Available in stainless steel or powder-coated options (C3 corrosion class).

Discharging Stations

Robust big bag and box discharging stations support forklift loading, integrated weighing, and automation for seamless unloading processes.

Why Choose NUGA RECYTECH?

Wide Application Range

Solutions designed for multiple industries and waste streams.

Scalable Systems

From stand-alone machines to complete turnkey plants.

Tailor-Made Recycling Solutions for Diverse Industries

Headquarter

Bozidara Adzije 19

44000 Sisak

Croatia

Production

Mala Svarca 155

47000 Karlovac

Croatia

Contact Us

+385 91 3636398

nuga@nuga-recytech.com

© 2012 - 2025 NUGA RECYTECH d.o.o. • All Rights Reserved • Developed by DobarPotez